Diesel Mechanic Near Me – Trusted Truck & Engine Repair 2025

Finding a reliable diesel mechanic near me has become a critical need for truck owners and fleet operators. These skilled professionals are essential to the transportation industry, ensuring that diesel-powered vehicles operate efficiently and safely on our roads.

A diesel mechanic near me expertise goes beyond simple repairs. They handle:

- Complex engine diagnostics

- Preventive maintenance

- Emergency repairs

- System upgrades

- Performance optimization

The demand for qualified diesel technicians is on the rise, with industry projections indicating a 28% growth rate by 2025. This increasing need is driven by:

- Rising commercial fleet operations

- Growing complexity of diesel engines

- Stricter emission standards

- Integration of advanced technologies

Diesel technician training programs have adapted to meet these industry demands. Modern training facilities now provide students with practical experience in:

- Advanced diagnostic tools

- Electronic control systems

- Alternative fuel technologies

- Emission control systems

The field offers promising career opportunities, with skilled technicians earning competitive salaries and enjoying job security. Whether you require repair services or are considering a career path, understanding the role of diesel mechanic near me will help you make informed decisions about your vehicle maintenance needs or professional future.

Table of Contents

Understanding the Role of Diesel Mechanic near me

A diesel mechanic’s daily responsibilities extend far beyond basic engine repairs. These skilled professionals handle complex tasks across various diesel systems maintenance areas:

Core Daily Tasks:

- Performing comprehensive engine diagnostics

- Rebuilding and repairing diesel engines

- Inspecting and repairing brake systems

- Testing electrical components and circuits

- Analyzing fuel injection systems

- Maintaining transmission and drivetrain components

- Conducting emissions control system checks

Preventive maintenance inspection serves as a crucial aspect of a diesel mechanic’s work. Taking this proactive stance allows for early detection of potential issues, preventing them from developing into significant problems.

Key Preventive Maintenance Areas:

- Oil and filter changes

- Fuel system cleaning

- Air system inspection

- Cooling system maintenance

- Belt and hose examinations

- Battery testing

- Tire rotation and alignment checks

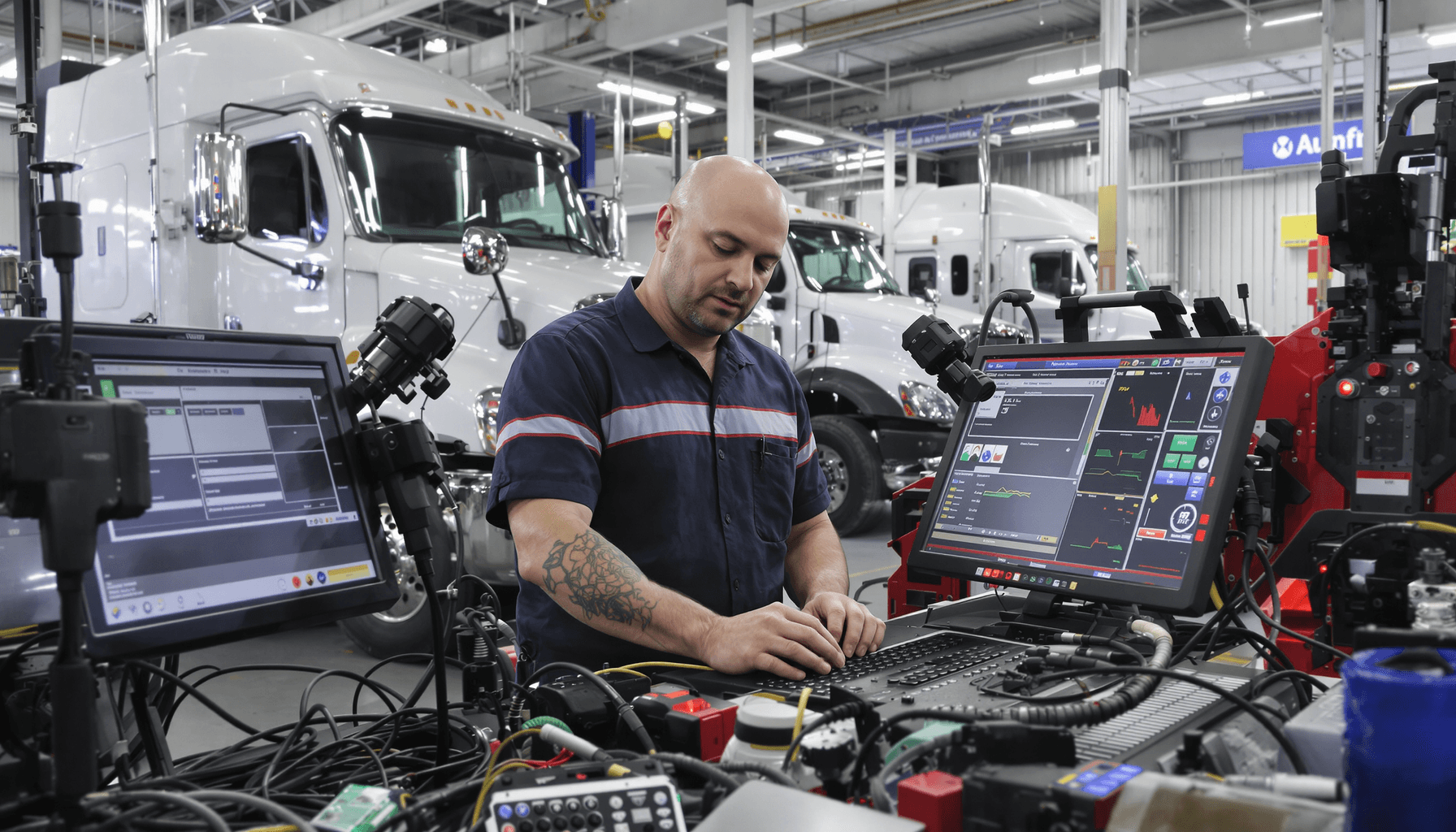

Today’s diesel technicians depend on advanced diagnostic technology and specialized tools to carry out their tasks efficiently.

Essential Diagnostic Equipment:

- Digital diagnostic scanners

- Multimeters for electrical testing

- Compression testers

- Fuel pressure gauges

- Laptop computers with specialized software

- Dynamometers

- Smoke opacity meters

The position requires both physical stamina and specialized skills, since mechanics frequently:

- Lift heavy components

- Work in confined spaces

- Read and interpret complex technical manuals

- Use computerized diagnostic equipment

- Maintain detailed service records

- Communicate technical information to customers

A regular workday often includes handling several vehicles, each presenting different problems, which leads mechanics to:

- Assess repair needs

- Estimate repair costs

- Order necessary parts

- Complete repairs within specified timeframes

- Test repaired systems

- Document all work performed

Safety protocols play a vital role in daily operations:

- Following OSHA guidelines

- Using appropriate personal protective equipment

- Maintaining clean work areas by ensuring proper ventilation

- Properly disposing of hazardous materials

- Implementing proper lifting techniques

These experts need to remain up-to-date with advancements in diesel engine technology, such as:

- Electronic control systems

- Alternative fuel systems

- Emission control technologies

- Advanced diagnostic procedures

- New repair techniques

Specializations within Diesel Mechanic Near Me

Diesel mechanics have the opportunity to focus on particular areas of the trade, allowing them to build specialized skills. This expertise can lead to greater earning potential and career growth. Below are some of the main specialization options available:

1. Air Brake Systems

- Inspection and maintenance of air brake components

- Testing air pressure systems and identifying leaks

- Repair and replacement of brake chambers, valves, and lines

- Certification in air brake diagnostics and repair procedures

- Safety compliance with DOT regulations

2. Electrical Systems

- Advanced diagnostics of electronic control modules

- Repair of starting and charging systems

- Troubleshooting complex electrical circuits

- Programming and updating engine management software

- Integration of telematics and GPS systems

3. Fuel Systems

- Fuel injection system maintenance and repair

- Common rail system diagnostics

- High-pressure pump rebuilding

- Emissions control system service

- Alternative fuel system adaptation

4. Heavy Equipment Specialization

- Hydraulic system repair

- Construction equipment maintenance

- Mining machinery service

- Agricultural equipment repair

- Material handling equipment diagnostics

5. Marine Diesel Systems

- Boat engine maintenance

- Propulsion system repair

- Generator set service

- Cooling system maintenance

- Marine-specific emissions compliance

Specialized training in these areas requires dedicated coursework and hands-on experience. Many technical schools offer targeted programs for each specialization such as those found in diesel mechanic courses. Manufacturers like Cummins, Detroit Diesel, and Caterpillar provide specialized certification programs for their specific systems.

The investment in specialized training pays off through:

- Higher hourly rates for specialized work

- Increased job security

- Access to manufacturer-specific repair contracts

- Opportunities for leadership positions

- Ability to work on advanced systems

Diesel mechanic Near me who pursue specializations often become go-to experts in their field. A mechanic specialized in electrical systems might focus exclusively on complex diagnostic work, while a fuel system specialist could build a reputation for solving challenging emissions issues.

Modern diesel engines incorporate sophisticated technology, making specialized knowledge essential. As systems become more complex, mechanics with deep expertise in specific areas become invaluable to repair shops and fleet operations.

Qualifications and Certifications for Diesel Technicians

Securing the right certifications sets you apart in the diesel mechanic industry. The Automotive Service Excellence (ASE) certification is the gold standard for diesel technicians, offering specialized credentials for medium and heavy truck systems.

Essential ASE Certifications Include:

- ASE Entry-Level Medium/Heavy Truck Brakes

- ASE Entry-Level Medium/Heavy Truck Electrical/Electronic Systems

- ASE Entry-Level Medium/Heavy Truck Diesel Engines

- ASE Entry-Level Medium/Heavy Truck Suspension & Steering

Your path to certification requires a combination of hands-on experience and technical knowledge. Most ASE certifications demand two years of documented work experience, paired with passing the corresponding certification exam.

Basic Educational Requirements:

- High school diploma or equivalent

- Post-secondary diesel technology program completion

- Valid commercial driver’s license (CDL)

- State-specific licensing requirements

Many employers prioritize certified technicians when you search for a “diesel mechanic near me.” These credentials demonstrate your commitment to professional excellence and technical proficiency.

Additional Valuable Certifications:

- Manufacturer-specific certifications (Cummins, Detroit Diesel, etc.)

- EPA Section 609 Certification

- Mobile Air Conditioning Society (MACS) Certification

- Alternative Fuel Systems Certification

- Army MOS 91B Certification

The certification process involves rigorous testing of your knowledge across multiple areas:

- Engine repair and diagnostics

- Brake systems maintenance

- Electrical system troubleshooting

- Preventive maintenance procedures

- Safety protocols and regulations

Maintaining your certifications requires periodic recertification, typically every five years. This ensures you stay current with evolving technology and industry standards in diesel engine repair and maintenance.

Choosing a Trusted Diesel Mechanic Near Me

Finding a reliable diesel mechanic requires careful research and attention to specific quality indicators. Here’s what you need to look for when selecting a trusted professional:

Professional Credentials and Shop Standards

- Valid ASE certifications displayed in the shop

- Clean, organized workspace with modern diagnostic equipment

- Professional repair order processing systems

- Clear documentation of all maintenance procedures

- Written estimates before work begins

Research Methods for Finding Quality Services

- Check online reviews across multiple platforms

- Look for detailed customer feedback about specific repairs

- Verify Better Business Bureau ratings

- Ask local trucking companies for recommendations

- Contact your local trucking association

Red Flags to Watch For

- Reluctance to provide written estimates

- Pressure to approve unnecessary repairs

- Lack of proper shop operation practices

- Limited or no warranty on repairs

- Unclear communication about repair timelines

Questions to Ask Potential Mechanics

- “What experience do you have with my specific engine type?”

- “Can you provide references from long-term clients?”

- “What warranties do you offer on parts and labor?”

- “Do you use OEM or aftermarket parts?”

- “How do you handle emergency repairs?”

Shop Evaluation Checklist

- Proper equipment for diesel diagnostics

- Clean, professional work environment

- Organized parts inventory system

- Clear pricing structure

- Experienced staff with ongoing training

A reputable diesel mechanic will maintain transparent shop operation practices, including detailed repair order processing and comprehensive documentation. You’ll want to visit potential shops during business hours to observe their workflow and interact with staff. Pay attention to how they handle customer inquiries and whether they take time to explain repairs thoroughly.

Exploring Training Programs for Aspiring Diesel Technicians

Diesel technician training programs offer structured pathways to launch your career in this growing field. Let’s examine the key program types and what you can expect in terms of investment and timeline.

1. Technical Schools and Community Colleges

- Program Duration: 6-24 months

- Average Tuition: $5,000-$15,000

- Start Dates: Multiple intakes (January, May, September)

- Curriculum Focus: Hands-on training, diagnostic techniques, engine repair

2. Manufacturer-Specific Programs

- Program Duration: 12-18 months

- Average Tuition: $15,000-$25,000

- Start Dates: Quarterly enrollments

- Specialized Training: Brand-specific tools, technologies, repair procedures

3. Certificate Programs

- Program Duration: 3-6 months

- Average Tuition: $2,500-$7,000

- Start Dates: Monthly rolling admissions

- Focus Areas: Basic diesel maintenance, preventive care, safety protocols

4. Associate Degree Programs

- Program Duration: 2 years

- Average Tuition: $20,000-$30,000

- Start Dates: Fall and Spring semesters

- Added Benefits: Business management courses, advanced diagnostics

Many programs include essential components to prepare you for real-world scenarios:

- Live workshop experience

- Virtual simulation training

- Industry partnership opportunities

- Job placement assistance

- ASE certification prep

Financial Aid Options

If you’re concerned about the cost of your chosen program, there are several financial aid options available:

- Federal grants

- Merit-based scholarships

- Industry sponsorships

- Payment plans

- Veterans benefits

Program Selection Criteria

When researching potential programs, keep these factors in mind:

- Accreditation status

- Job placement rates

- Industry partnerships

- Available equipment/facilities

- Instructor expertise

The most successful programs combine classroom instruction with extensive hands-on training. You’ll work with actual diesel engines, diagnostic equipment, and repair tools under expert supervision. Many schools maintain partnerships with local businesses, creating direct pathways to employment after graduation.

Class sizes typically range from 15-20 students, ensuring individual attention and adequate access to training equipment. Programs often include evening and weekend options to accommodate working students. Some schools offer hybrid learning models, combining online coursework with in-person labs or workshops for added flexibility in scheduling and location.

The Value of Apprenticeships in Diesel Mechanic Careers

Apprenticeships serve as a powerful gateway into the diesel mechanic profession, offering hands-on experience under the guidance of seasoned professionals. You’ll work directly with experienced mechanics, learning practical skills while earning a paycheck.

Key Benefits of Diesel Mechanic Apprenticeships:

- Real-world experience with diverse engine types and repair scenarios

- Direct mentorship from certified professionals

- Paid training while learning the trade

- Network building within the industry

- Immediate application of theoretical knowledge

The typical apprenticeship program spans 3-4 years, combining on-the-job training with classroom instruction. You’ll start with basic maintenance tasks and progressively tackle more complex repairs as your skills develop.

Financial Aid Options for Aspiring Diesel Technicians

The FastForward Credential Grant provides substantial financial support for diesel technician training, covering up to two-thirds of your program costs. This grant specifically targets high-demand fields like diesel mechanics.

Additional funding sources include:

- Industry-specific scholarships from manufacturers like Cummins and Detroit Diesel

- Federal Pell Grants for qualifying students

- State-specific workforce development grants

- Veterans’ educational benefits

- Trade union scholarships

Many local diesel mechanic shops partner with apprenticeship programs, making it easier to find opportunities near you. These partnerships create a direct pipeline from training to employment, often leading to full-time positions after program completion.

Apprenticeship Program Structure:

- First Year: Basic maintenance, safety protocols, tool familiarization

- Second Year: Engine diagnostics, brake systems, electrical components

- Third Year: Advanced repairs, specialized systems, troubleshooting

- Fourth Year: Complex diagnostics, team leadership, business operations

The combination of structured learning and practical experience makes apprenticeships an invaluable stepping stone in your diesel mechanic career. Your search for “diesel mechanic near me” can lead to apprenticeship opportunities at local repair shops, dealerships, and fleet maintenance facilities.

During these apprenticeships, you’ll gain real-world experience with diverse engine types and repair scenarios which will be instrumental in shaping your career.

Future Trends Shaping the Field of Diesel Mechanics

The diesel mechanic industry is going through a rapid technological evolution. In Southside Virginia, experienced technician Suzanne Shook notes that modern diesel engines require advanced diagnostic tools and computer-based systems for maintenance and repair.

Key technological advancements transforming diesel mechanics:

- Electric and hybrid diesel systems

- Advanced telematics for remote diagnostics

- AI-powered predictive maintenance tools

- Alternative fuel compatibility

- Smart sensor technology

The integration of electric components in diesel engines creates new opportunities for mechanics. When searching for a “diesel mechanic near me,” you’ll find professionals adapting their skills to work with hybrid powertrains and electric auxiliary systems.

Essential skills for future diesel technicians:

- Computer diagnostics proficiency

- Electric system troubleshooting

- Data analysis capabilities

- Software update management

- Alternative fuel system knowledge

The rise of autonomous vehicles and fleet management systems demands mechanics stay current with software-based maintenance. Diagnostic tools now connect to cloud platforms, enabling real-time monitoring and predictive maintenance scheduling.

Adaptation strategies for diesel mechanics:

- Regular certification updates

- Online technical training courses

- Manufacturer-specific workshops

- Industry conference attendance

- Networking with technology providers

Environmental regulations drive innovation in diesel engine design. Mechanics must understand emission control systems, particulate filters, and selective catalytic reduction technology. The push toward cleaner diesel engines creates specialized repair needs.

The future success of diesel mechanics depends on embracing these technological changes. Training programs now incorporate advanced diagnostic equipment and computer-based learning modules. Mechanics who combine traditional mechanical expertise with modern technical knowledge position themselves as valuable assets in this evolving field.

FAQs (Frequently Asked Questions)

What does a diesel mechanic do and why is it important to find a reliable diesel mechanic near me?

A diesel mechanic specializes in the maintenance, repair, and inspection of diesel engines and related systems. Having a reliable diesel mechanic nearby ensures timely preventive maintenance and repairs, which are crucial for the longevity and optimal performance of diesel-powered vehicles and equipment.

What are the key responsibilities of a diesel mechanic in maintaining diesel systems?

Diesel mechanics perform routine preventive maintenance inspections, diagnose issues using specialized tools, repair or replace faulty components, and ensure that diesel systems operate efficiently. Preventive maintenance is vital to avoid costly breakdowns and extend engine life.

What specializations can a diesel mechanic pursue to enhance their expertise?

Diesel mechanics can specialize in areas such as air brakes training, electrical systems repair, and fuel systems service. Pursuing specialized training in these fields improves job prospects and allows mechanics to handle complex repairs with greater proficiency.

Which qualifications and certifications are essential for aspiring diesel technicians?

Aspiring diesel technicians should aim for certifications like ASE Entry-Level Medium/Heavy Truck Brakes and ASE Entry-Level Medium/Heavy Truck Electrical/Electronic Systems. These certifications validate skills and knowledge necessary for working on medium to heavy-duty trucks.

How can I choose a trusted diesel mechanic near me?

To find a reliable diesel mechanic locally, check for proper certifications, read customer reviews, seek recommendations from trusted sources, evaluate shop operation practices, and inquire about their repair order processing methods to ensure professionalism and quality service.

What training programs and financial assistance options are available for aspiring diesel technicians?

Various diesel technician training programs offer comprehensive education on diesel systems with details on program start dates and tuition costs. Apprenticeships provide hands-on experience, while financial assistance options like FastForward Credential Grants and scholarships help offset training expenses.

epicureanstay.com

epicureanstay.com