Mannacote 2025 – Innovative Coating You Can Rely On

Understanding Mannacote: A Multifunctional Product Across Industries

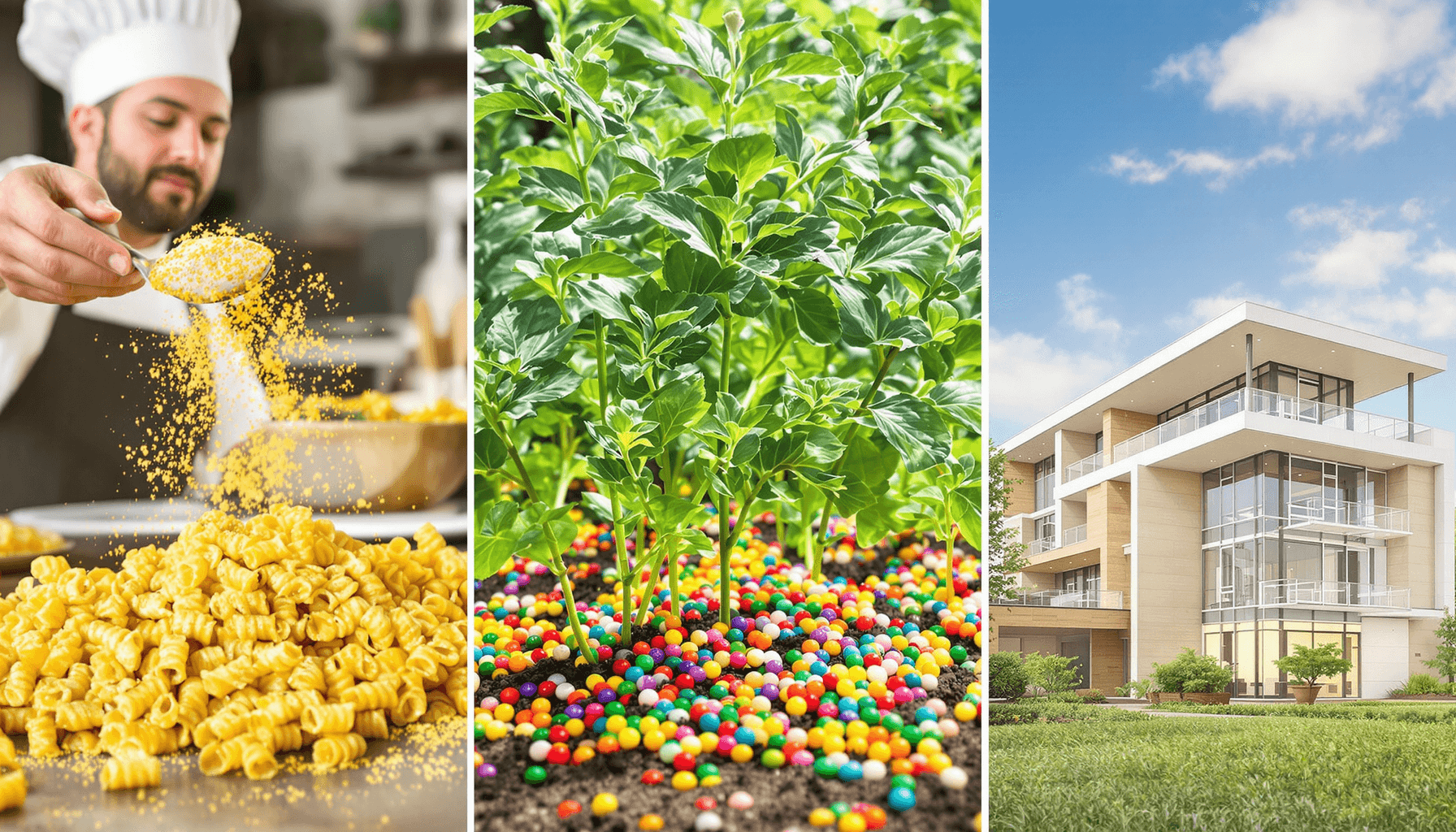

Mannacote is a versatile term with different meanings in various industries. Its interpretation depends on the specific context in which it is used:

- Culinary: A specialized powder that transforms the preparation of stuffed pasta dishes, particularly manicotti.

- Agricultural: A controlled-release fertilizer engineered for optimal plant nutrition.

- Construction: A natural composite material used in building and design applications.

The exact meaning of Mannacote becomes clear through its context of use. A chef looking for Mannacote to prepare pasta needs a different product than a gardener seeking to fertilize plants or an architect specifying materials for sustainable construction.

This article explores three primary applications of Mannacote:

- A culinary secret weapon that prevents pasta shells from cracking while enhancing sauce absorption.

- An innovative fertilizer featuring temperature-controlled nutrient release and color-coded granules.

- A sustainable building material combining natural fibers and resins for durability and design flexibility.

Understanding these distinct applications helps avoid confusion and ensures the right form of Mannacote is selected for specific needs. Each variation offers unique benefits within its respective field, demonstrating the product’s remarkable adaptability across industries.

Table of Contents

1. Mannacote in Culinary Applications

The culinary world’s best-kept secret for perfect stuffed pasta lies in a specialized powder called Mannacote. This remarkable ingredient transforms ordinary pasta dishes into restaurant-quality creations by addressing common challenges faced when preparing stuffed pasta varieties.

The Magic Behind Perfect Manicotti

Mannacote’s primary function revolves around its ability to create the ideal pasta texture while preventing common issues:

- Crack Prevention: The powder forms a protective layer that maintains pasta integrity, helping to keep pasta shapes intact.

- Enhanced Sauce Absorption: Creates microscopic surface channels for better sauce adherence

- Moisture Balance: Regulates water content to prevent sogginess or dryness

- Texture Enhancement: Produces silky-smooth pasta without compromising authentic flavor

Compatible Pasta Varieties

Mannacote works exceptionally well with multiple pasta types:

- Jumbo shells

- Cannelloni tubes

- Lasagna sheets

- Fresh pasta dough

- Traditional manicotti

Essential Application Method

Step 1: Par-boiling

- Bring water to rolling boil

- Cook pasta for 4-5 minutes

- Remove while still firm

- Drain and lay flat on clean kitchen towel

Step 2: Mannacote Application

- Sprinkle powder evenly on both sides

- Use approximately 1/4 teaspoon per pasta piece

- Ensure complete coverage

- Let rest for 2 minutes

Step 3: Stuffing Process

- Fill pasta while still flexible, but be cautious not to overstuff as this could lead to stuffing-related food safety issues.

- Seal ends properly

- Place in baking dish with minimal overlap

Professional Baking Guidelines

Temperature Settings

- Conventional oven: 375°F (190°C)

- Convection oven: 350°F (175°C)

Timing

- Covered baking: 20-25 minutes

- Uncovered finish: 5-10 minutes

- Internal temperature should reach 165°F (74°C)

Moisture Retention Tips

- Sauce Application: Layer bottom of baking dish with sauce before adding pasta, which will also help in retaining moisture.

- Coverage: Use enough sauce

2. MannaCote as an Agricultural Fertilizer

Manna Cote is a significant advancement in controlled-release fertilizer technology, designed to meet the precise nutritional needs of various crops while maintaining environmental sustainability. This innovative fertilizer system utilizes temperature-sensitive coating technology to regulate nutrient release, providing consistent plant nutrition over extended periods.

Features and Benefits of Manna Cote Fertilizer

1. Intelligent Nutrient Release System

- Temperature-activated coating technology

- Steady nutrient distribution spanning 3-6 months

- Customized release patterns based on plant growth cycles

- Synchronized delivery with peak nutrient demand periods

2. Color-Coded Application System

- Green granules: 3-month release duration

- Blue granules: 4-month release duration

- Yellow granules: 6-month release duration

- Visual verification for accurate application rates

- Simple inventory management and timing control

3. Protective Nutrient Release

- Specialized coating prevents initial nutrient surge

- Eliminates root burn risk common in conventional fertilizers

- Balanced release pattern matches plant uptake capacity

- Protection against nutrient lockout in varying soil conditions

4. Environmental Performance

- 85% reduction in nutrient leaching compared to standard fertilizers

- Minimal groundwater impact

- Reduced greenhouse gas emissions from fertilizer application

- Lower application frequency decreases soil compaction

5. Crop-Specific Benefits

Container Plants

- Consistent feeding throughout growing cycle

- Reduced salt accumulation

- Enhanced root development

- Improved drought resistance

Field Crops

- Single application coverage for entire growing season

- Uniform crop development

- Reduced fertilizer loss during rainfall

- Improved nutrient absorption efficiency

Nursery Applications

- Precise nutrition control for sensitive species

- Reduced labor costs through fewer applications

- Better plant establishment rates

- Enhanced stress tolerance

Technical Specifications of Manna Cote Fertilizer

Here are the technical specifications of Manna Cote fertilizer:

- Polymer coating thickness: 20-25 microns

- Nutrient release activation temperature: 21°C (70°F)

- Available NPK ratios: 14-14-14, 18-6-12, 15-9-12

Application Guidelines for Manna Cote Fertilizer

Successful application of Manna Cote fertilizer requires specific techniques tailored to different agricultural environments. Here’s a detailed guide for optimal results:

Field Crop Applications

- Mix Manna Cote into soil at a depth of 4-6 inches before planting

- Apply in bands 2-3 inches away from seed rows

- Use 2-3 pounds per 100 square feet for heavy feeders

- Reduce rates by 25% for light-feeding crops

Container Plant Guidelines

- Incorporate fertilizer into potting mix before planting

- Use 1-2 tablespoons per gallon of container size

- Place fertilizer in the root zone, avoiding direct contact with stems

- For established plants, create 2-inch deep holes around drip line

- Space holes 6-8 inches apart for even nutrient distribution

Protected Cultivation Specifications

The unique polymer coating of Manna Cote remains stable under:

- Glass greenhouse conditions

- High tunnel environments

- Plastic hoop houses

- Temperature ranges of 40-95°F

Crop-Specific Application Rates

Ornamental Plants

- Annuals: 3-4 lbs per 100 sq ft

- Perennials: 4-5 lbs per 100 sq ft

- Woody ornamentals: 5-6 lbs per 100 sq ft

Edible Crops

- Vegetables: 4-5 lbs per 100 sq ft

- Fruit trees: 6-8 lbs per 100 sq ft

- Berries: 3-4 lbs per 100 sq ft

Environmental Considerations

- Apply during morning hours

- Avoid application before heavy rain forecasts

- Maintain consistent soil moisture

- Monitor soil temperature for optimal release rates

Safety Precautions

- Wear gloves during application

- Keep fertilizer dry until use

- Store in original container

- Maintain application records for future reference

The temperature-sensitive coating technology responds to soil conditions, releasing nutrients gradually as plants need them. This gradual release is similar to the approach used in the Feed Me Seymour program, which emphasizes the importance of understanding plant nutrient needs and delivering them effectively.

3. Mannacote as a Natural Composite Material

Mannacote is an innovative composite material made from natural fibers and environmentally friendly resins. It offers a sustainable alternative to conventional building materials without compromising on performance.

Core Components and Structure

The material’s foundation consists of:

- Natural plant fibers such as hemp, jute, or bamboo

- Bio-based resins derived from sustainable sources

- Mineral additives for enhanced properties

- Non-toxic binding agents

Key Performance Characteristics

Moisture Resistance

- Water-repellent surface treatment

- Resistant to warping and swelling

- Suitable for high-humidity environments

- Mold and mildew resistant

Structural Integrity

- High tensile strength

- Impact resistant

- Dimensional stability

- Load-bearing capacity comparable to engineered wood

Weight and Handling

- 40% lighter than traditional composites

- Easy installation and transportation

- Reduced structural load on buildings

- Cost-effective shipping and handling

Applications Across Industries

Construction

Mannacote can be used in various construction applications including:

- Wall panels and cladding

- Flooring systems

- Ceiling tiles

- Interior partitions

Furniture Manufacturing

In the furniture sector, Mannacote serves as a versatile material for:

- Table tops

- Cabinet doors

- Shelving units

- Decorative panels

Outdoor Installations

The durability of Mannacote makes it ideal for outdoor installations such as:

- Decking

- Fencing

- Garden furniture

- Architectural elements

Advantages of Using Mannacote Material in Construction and Design

Environmental Benefits

The production process of Mannacote is carbon-negative, which means it helps reduce greenhouse gas emissions. Other environmental advantages include:

- Zero volatile organic compounds (VOCs)

- 100% recyclable at end of life

- Reduced carbon footprint compared to synthetic materials

Design Flexibility

Mannacote offers extensive design flexibility with features such as:

- Custom color matching capabilities:

- Natural earth tones

- Contemporary metallics

- Custom pigmentation with UV-stable finishes

- Multiple surface texture options

- Seamless integration with existing materials

- Pattern and finish variations

Thermal Performance

Mannacote exhibits excellent thermal performance with an R-value comparable to fiberglass insulation, offering benefits like:

- Temperature regulation properties

- Reduced heating and cooling costs

- Natural sound dampening qualities

With its unique blend of sustainability, versatility, and performance, Mannacote is set to revolutionize multiple industries including construction, furniture manufacturing, and outdoor installations.

Comparing the Different Uses of Mannacote

Mannacote’s diverse applications showcase distinct characteristics across three primary domains:

1. Culinary Powder

- Fine, powdery texture designed for pasta preparation

- Direct food contact application

- Short-term effectiveness during cooking process

- Specific focus on moisture retention and texture enhancement, which is crucial for achieving the desired consistency in pasta dishes.

- Used in small quantities per application

2. Agricultural Fertilizer

- Granular form with color-coding system

- Temperature-responsive coating technology

- Long-term effectiveness (3-6 months)

- Precise nutrient release control

- Applied in larger quantities for crop nutrition

3. Natural Composite Material

- Solid structural form

- Permanent installation or long-term use

- Physical properties focus (strength, durability)

- Customizable aesthetic features

- Used in construction and manufacturing

The term “Mannacote” requires careful attention to context for proper identification. A chef seeking Mannacote for pasta preparation needs a different product than a farmer planning crop fertilization or an architect specifying building materials. Each variant serves a specialized purpose within its respective industry, utilizing different physical forms and chemical compositions to achieve targeted results.

These distinct applications demonstrate how a single term can represent multiple innovative solutions across different sectors, each developed to address specific challenges in food preparation, agriculture, and sustainable materials. For instance, the culinary powder variant not only focuses on moisture retention and texture enhancement during cooking but also has been studied extensively for its effects on food texture, as highlighted in various application studies by Texture Technologies.

Conclusion

Mannacote is a great example of how one term can represent different innovations in various industries. Each form of Mannacote brings unique value to its specific field:

Culinary Applications:

- Creates perfect stuffed pasta dishes

- Prevents shell cracking

- Enhances sauce absorption

- Delivers silky, tender texture

Agricultural Benefits:

- Temperature-controlled nutrient release

- Color-coded application system

- Reduced environmental impact

- Extended feeding duration

Natural Composite Material:

- Sustainable construction alternative

- Moisture-resistant properties

- Design flexibility

- Energy-efficient insulation

The versatility of Mannacote opens doors for diverse applications – from professional chefs seeking pasta perfection to farmers maximizing crop yields, and architects designing sustainable buildings. Each variant of Mannacote addresses specific challenges within its field while maintaining core principles of efficiency and innovation.

Whether you’re in the culinary arts, agriculture, or sustainable construction, understanding the specific type of Mannacote relevant to your needs unlocks its full potential. The product’s adaptability across industries showcases its significance as a multifunctional solution in modern applications.

FAQs (Frequently Asked Questions)

What is Mannacote and why is understanding its context important?

Mannacote is a multifunctional product with multiple meanings across different industries, including culinary, agricultural, and material applications. Understanding the context when referring to Mannacote is crucial to avoid confusion and to appreciate its unique benefits in each domain.

How does Mannacote enhance the preparation of stuffed pastas like manicotti?

In culinary applications, Mannacote acts as a secret ingredient that prevents cracking and improves sauce absorption in pasta shells. Applied as a powder during par-boiling, it results in silky, tender pasta textures without altering flavor. It works well with various pasta types such as jumbo shells, cannelloni, and lasagna rolls.

What are the key features and benefits of Manna Cote as an agricultural fertilizer?

Manna Cote fertilizer utilizes innovative slow-release coating technology that regulates nutrient release based on temperature. Its color-coded granules help identify optimal application timing. Benefits include low initial nutrient release preventing plant damage or nutrient burn, enhanced nutrient use efficiency, and reduced environmental runoff risks.

How should Manna Cote fertilizer be applied for optimal results in agriculture?

Manna Cote should be applied considering crop type and growing conditions. It suits nursery plants, perennials, container plants, and ornamental crops. The temperature-sensitive nutrient release provides 3-6 months of nutrition. Best practices include adjusting application rates for field versus protected cultivation (greenhouse) environments to maintain fertilizer stability under glass or plastic covers.

What makes Mannacote a valuable natural composite material in construction and design?

As a natural fiber composite made from fibers and resins, Mannacote offers moisture resistance, lightweight durability, and insulating properties. It is eco-friendly compared to synthetic alternatives and offers customizable colors and textures. Its versatility allows use in flooring, wall coverings, furniture manufacturing, and outdoor installations while contributing to energy-efficient buildings.

How do the different uses of Mannacote compare across culinary, agricultural, and material fields?

Mannacote serves distinct purposes depending on its form: as a culinary powder enhancing stuffed pasta texture; as an agricultural slow-release fertilizer improving nutrient efficiency; and as a natural composite material offering sustainable building solutions. Recognizing these differences is essential for appropriate application and maximizing benefits within each industry.